Earlier this year, we launched Rhino UV Armor Signs, our proprietary sign manufacturing process that can produce signs of unmatched quality at unmatched prices.

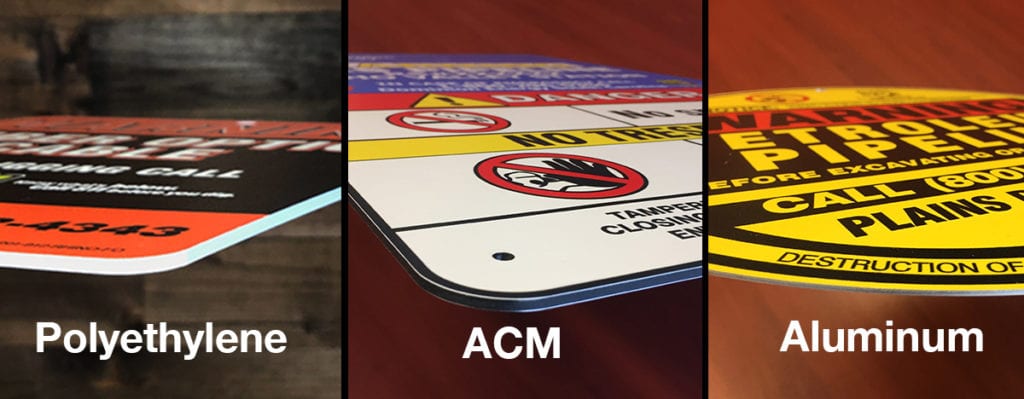

When it comes to making your signs, we are all about choices. Different situations and environments call for different materials when producing your signs. We have three options to best fit your needs, each with a focus on durability: polyethylene, aluminum composite material (ACM), and aluminum.

Each substrate offers certain advantages as well as detriments when compared to each other, and one should consider all relevant factors when selecting your material.

Polyethylene (HDPE)

Made from high-density polyethylene resin, these signs are environmentally friendly and extremely cost-effective.

Pros ✅

- inexpensive

- lightweight

- UV Stable

- No scrap value

- Gunshot resistant

Cons 🚫

- size limitations

- lower rigidity

- risk warping in certain conditions.

.

Aluminum Composite Material (ACM)

ACM is comprised of two thinly-sliced sheets of aluminum thermo-bonded to a polyethylene core.

Pros ✅

- Starts flat, stays flat – will not warp

- Weighs 50% less than aluminum

- Twice as rigid as aluminum

- Easy to cut into custom shapes

- No scrap value

Cons 🚫

- More expensive than Poly

- Lower tensile strength

- not bendable

Aluminum

Aluminum has been the industry go-to since day one.

Pros ✅

- durable

- High-tensile strength

- bendable – can be used for multiple applications

Cons 🚫

- heavy

- expensive

- warp over time

- high-target for scrappers

.